AZ Hollink is proud to have BRUSH as a key customer for more then 15 years. BRUSH is the largest independent manufacturer of turbo generators in the world with manufacturing plants in de UK, The Netherlands and Czech Republic, and with customers across all continents, BRUSH has a truly good presence. Each manufacturing plant has been designated as a Centre of Excellence for the design and manufacture of high voltage generators, power management systems, excitation systems and motors (including synchronous, submersible and other special types).

Further BRUSH offers support for all its products by means of a global Aftermarket solution, providing support 365 days of the year, including replacement parts, servicing, maintenance and upgrades.

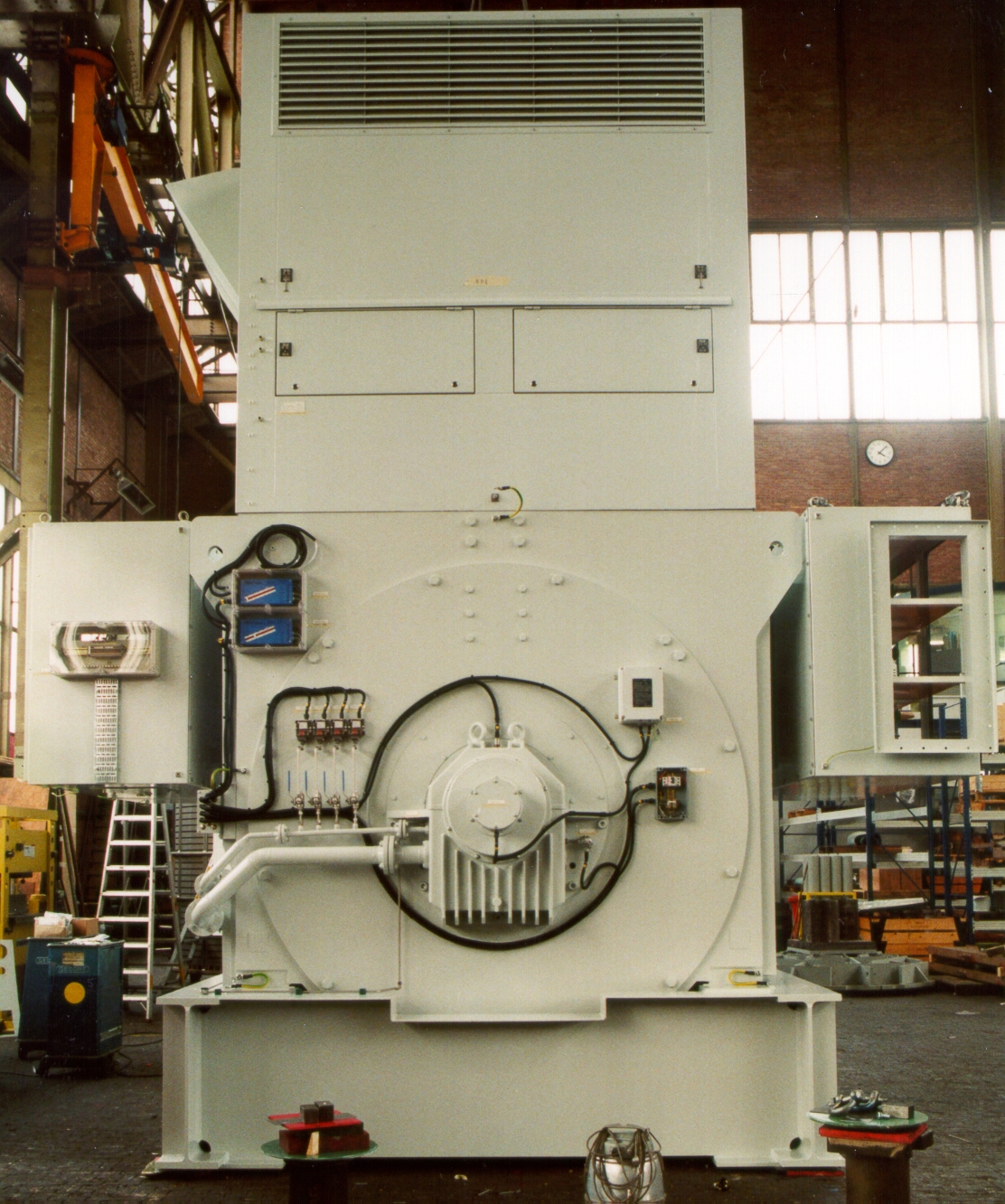

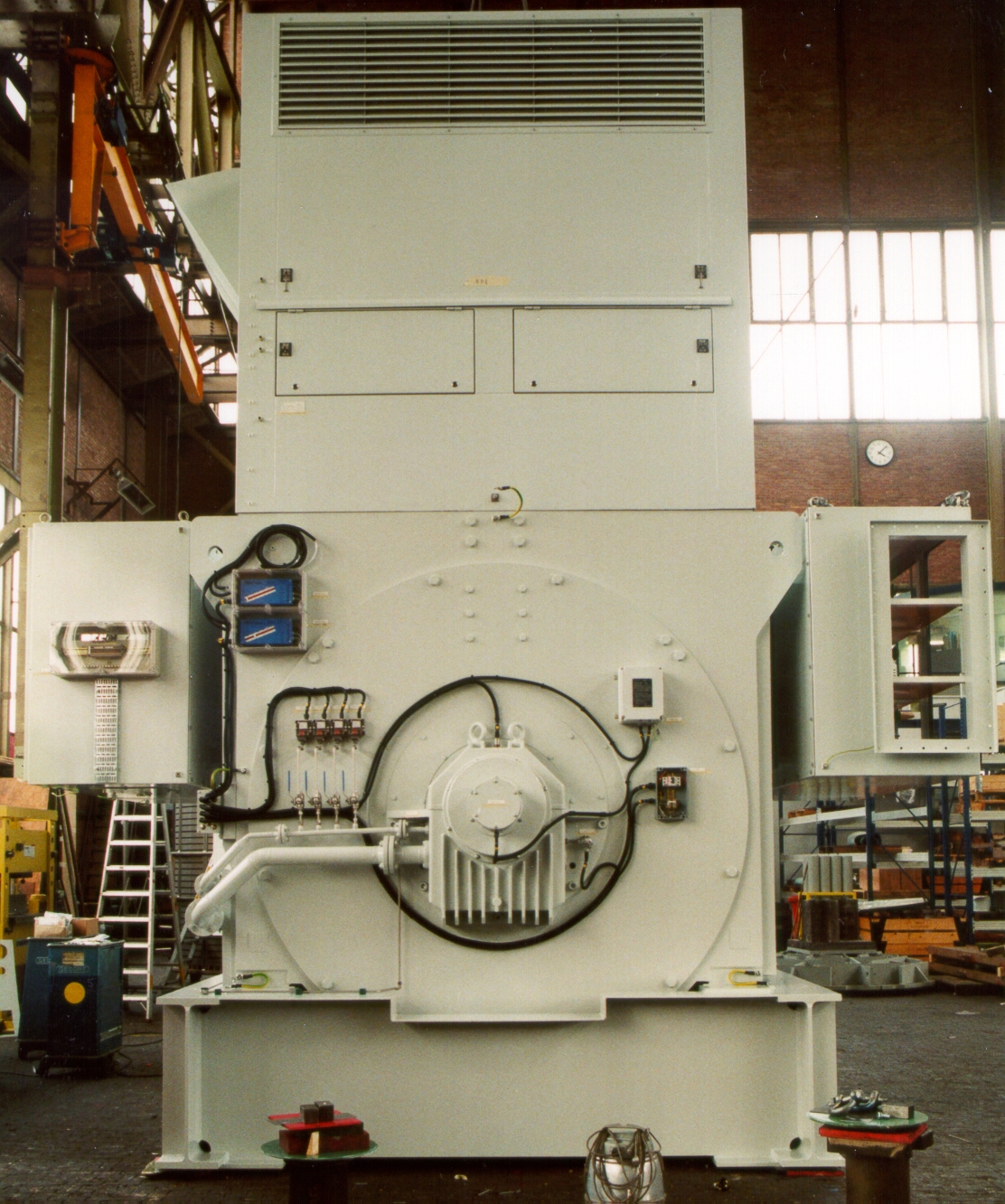

Dating back to 1882 and a pedigree of Smit Slikkerveer, Holec Machines and HMA Power Systems, BRUSH in The Netherlands is the Centre of Excellence for the design and manufacture of high voltage 4-pole synchronous generators from 10 up to 65 MVA. BRUSH NL supplied over 540 machines worldwide for the utility and industrial market, cogeneration, CHP and Oil & Gas exploration.

The 4-pole synchronous generators are driven by gas or steam turbines or aero derivative turbines.

BRUSH NL also manufactures specialist submersible motors, traction motors and provides service capabilities for numerous makes and types of large electrical rotating machines.

BRUSH in The Netherlands is an essential part of the BRUSH group, adding bespoke specialist capabilities to its New Build and Aftermarket services.

Safety on board vessels and rigs is of extreme importance. Not only when things are going right but especially when there is a calamity. European Transmission Company is proud to supply parts to the Harding Safety group to enable them so set the highest safety standards on life saving appliances on board vessels and rigs. By signing a long-term Global Agreement, European Transmission Company and Harding Safety express their long standing relationship. We see that it becomes more important for our customers not only to supply quality products in time, but also to act as a sparring partner to develop the best solutions.

European Transmission Company (ETC), is supplying a Europe-based manufacturer of fork lift trucks with precision couplings for the steering column. The coupling was selected following quality concerns over the customer’s previous supplier. The fork lift manufacturer was experiencing occasional failures with its previous steering column coupling due to the required load and driving speed. Due to the cost of repairing the fork lifts, as well as damage to the manufacturer’s reputation, the fork lift OEM turned to ETC, for an alternative solution. Extensive testing soon showed that the right decision had been taken, with Huco couplings duly specified for the company’s next generation fork lift, as well as replacing existing units in service.

With the coupling providing a connection between the steering column and the wheel set, quality and reliability is paramount. For this reason, in 2013, the decision was made to replace the couplings on all of the customer’s existing fork lifts in the field, with our solution. This amounted to around 3000 couplings, which were called-off in batches of 500. ETC then commenced deliveries of the coupling to the customer’s factory in the Netherlands for fitment to new-build models.

“We pride ourselves on our track record of never delivering late,” says Rob Hendriks, Managing Director of ETC. “In 2015, the customer moved some of its fork lift production to another country, but they are still ordering couplings from us. We now supply around 2000-3000 Huco couplings a year to this customer. In fact, it looks like they will be doubling their capacity in the near future at the new plant, which will lead to even more orders.”